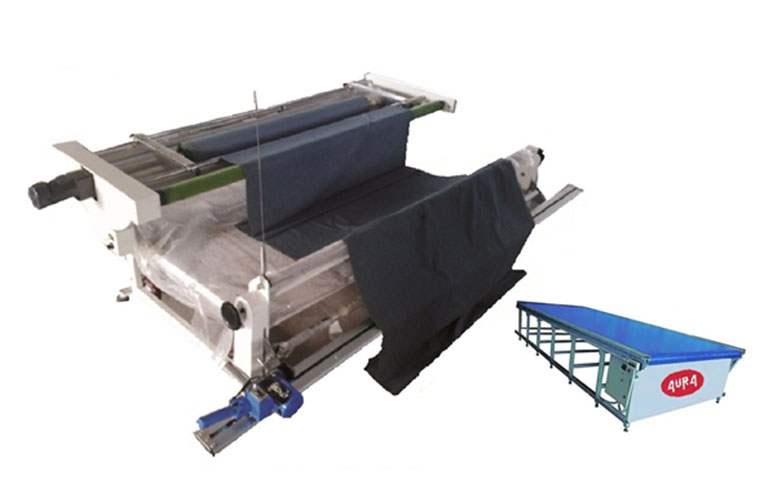

Fabric Inspection Machine

Compact – Efficient – Accurate Fabric Inspection Machine

Fabric Measuring and Inspection Machine ( Ultra-Premium Model) special Designs (4x1) machine Roll to Than, Than to Roll, Than to Than and Roll to Roll With Digital counter meter and End cutter Attached in the machine. relaxing Rollers controlled individually by individual controller

High Productivity Due To The Bright And Accurate Light On The Plates Which Enable Easy Detection In Any Part Of The Fabric.

Easy And Accurate Inspection Also Comes With PLC Control Where All The Functions Can Be Controlled Easily , Analog Length Counter ( Digital Metre Can Also Be Fixed On Special Request ) , High Productivity Easy And Accurate Inspection Also Comes With PLC Control Where All The Functions Can Be Controlled Easily , Analog Length Counter ( Digital Metre Can Also Be Fixed On Special Request ) , High Productivity Turbo Winding And Unwinding System Which Helps The Garment To Easily Wind And Unwind With The Help Of Buttons , This Makes The Machine Easy To Handle And Less Labour Intensive , LED Technology Which Saves 30% Power Consumption Than Any Other Machine This Helps In Saving Resources , Universal Model 4 In 1 With Machine Roll To Than, Than To Roll, Than To Than And Roll To Roll A special Tensioning device is provided to provide adjustable tension to the fabric during Inspection. With Emergency Stop facility to stop the machine at any time , as per the Safety and CE Norms. Complete with all accessories-tray for keeping loose fabrics, plastic pipes for rolling fabrics etc.

| Model | AG-93 (Ultra - Premium) | AG-93 (Premium ) | AG-93(Advantage) |

|---|---|---|---|

| Alignment Cloth Edge | √ | X | X |

| Forward & reverse system | √ | √ | X |

| Length Counter | Digital counter | Analog | Analog |

| Max Cloth Width | 1800 mm | 1800 mm | 1800 mm |

| Size Available from 1400 mm to 2800 mm | |||

| Inspection Speed | 0-24m/min | 0-24m/min | 0-24m/min |

| Back Roller | √ | √ | X |

Fabric Measuring and Inspection Machine (Kaigu) with defect counter meter & printer.(100% imported)

Fabric width adjustability; high productivity; easy and accurate inspection, analog length counter, high productivity Width: 1800 mm, with front rollers for winding & unwinding fabric, edge control system, relaxing system, defect counter meter & printer.

- This Equipment with its special Unwinding Roller placed at various locations helps in easy movement and also in removing the crease in the fabric while inspection.

- Forward & reverse motion facility is provided to enable effective inspection.

- Automatic edge control system helps the roll to foam evenly.

- The Length of the Fabric inspected is directly displayed by the Length Counter.

- The Digital fault counter helps in counting the number of defects in the fabric by giving the command to the printer.

- Emergency stop switch is provided to stop the machine suddenly in case of an emergency.

- Working with Both Length and Fault counters the operator can easily keep note of all the faults and also know at which length the fault are coming.

- Fabric relaxing system helps the than to be made evenly.

- Highly Suitable to check the all type of garment

Automatic Edge Aligning and Checking Machine (Fabric Inspection Machine Kaigu)

Features

Suitable for checking knitted cloth materials, used for cloth reeling, measuring and releasing equipped with electronic sensor for automatic edge alignment and back reeling. Unique electronic measuring device to ensure freely reeling. Unique electronic measuring device to sure freely reeling and releasing the material essential for large scale cloth knitting and weaving factories Capacity stating from: 1800mm to 3200 mm

| Alignment | Kaigu YB-180 WB |

|---|---|

| Alignment | Ϋ |

| Stir Cloth | Ϋ |

| Roll to Roll/ Than to roll/ Roll to Than/Than to Than | Ϋ |

| Length Consenter | Electric |

| Max. Cloth Width | 1800mm |

| Inspecting Speed | 0~24 m/min |

| Power | 1.5 kw |

| Electricity | 220V 1Ph 50Hz |

Fabric Relaxing Machine

- The machine is applicable to knit and woven material both. Relaxing width:82"& 90",we can also make other sizes up to customer's demand.

- This machine can relax the fabric with fast, well and edge accurate situation, so can be used in spreading machine with super efficient.

- Machine will stop automatically when out of fabric.

- The roller can be reversed for rolling up the fabric.

- The machine has been set up with bearing wheel, can be moved easily.

Model LD-200N / 82〞 LD-200N / 90〞

Power 1P / AC220V 50 / 60Hz 1P / AC220V 50 / 60Hz

Diameter 500 mm 500 mm

Max Loading 80kgs 90kgs

Max Width 82" 90"

Max Speed 60 yd / min 60 yd / min

Dimension 2430 x 780 x 1120 mm 2630 x 780 x 1120 mm

Weight of Machine 180 kg

Semi-Automatic spreading machine

Semi-Automatic spreading machine, spreading table

Contact Us For Technical SpecificationFeatures

- Spreading machine (size 1200-1800mm)

- With cutting function and motor controlled pulling attachment.

- With speed regulator.

- (Size: 1800mm width) with cutting function and motor controlled pulling attachment with speed regular.

- Elimination of manual spreading and layering of fabrics which is the weakest part of the cutting room production chain.

- Several times increase of spreading efficiency for each type of fabric.

- Only one operator results in significant reduction of work costs.

- Very fast spreading of matters for small series and single production orders.

- Spreading many kind of knitting and woven fabric.

- Electric count, insure high precise record.

- Automatic start checks control when machine is switched on.

- Ability to program all steps in a spread according to production need.

- Program to count spreading time and total spread meters.

- Digital touch screen.

- Fabric Auto cutting without tension.

- Automatic stop when fabric is used up.

Audaces Linea

Audaces Linea automatic spreader accelerates the production and marketing of your products. Schedule multiple same-day spreads with simple touches on the machine touch screen

- Tension control The spreads are made without tensioning the fabrics (or other materials). The machine is parameterized according to each material, ensuring quality in the finished piece. Fabric layers quality In addition to aligning the edges, Audaces Linea has the intelligence to count the length and number of layers established for each spread. It is also possible to interrupt the spreading process by identifying any fabric failure and either resume from the zero point or continue from the current point.

- Zero spacing and high cut quality. Cutting with zero spacing between the patterns, the machine sets the starting points automatically, guaranteeing cutting quality from the first to the last layer, with maximum use of raw material.

- The best cost-benefit ratio in the market. Manufactured with commercial electronics and first-line parts, Neocut Bravo guarantees low maintenance costs and energy savings. More time for your business to grow. Audaces solutions guarantee agility and time gain in the processes of spreading and cutting. We save your time so that you can plan the growth of your company.

- Low maintenance cost Manufactured with commercial electronics and first-line parts easily found on the market. And you even have specialized technical assistance.

Features

- Operator control panel (right or left)

- Automated cradle tilt system.

- Color computer touch screen with auto diagnosis system.

- Electronic control material tension system.

- Photocells Edges alignment placed on the moving base

- Infrared security sensors for automatic stop in case of obstacles

- Spreading with or without catchers

- Storage of different spreading programs

- Two-way cutter with variable speed and automatic lift

- Maximum speed 100 m/min

- Spreading height up to 22cm

- Diameter of fabric roll up to 60cm

- Maximum weight of fabric roll50kg

- Fabric width up to 180 cm

- Spreader connection with external pc and remote data transmission by software Linear Planner

Our Products

- Audaces Apparel Cad CAM

- Garment Cutting Printing Plotters

- Fabric Inspection Machine

- Conveyor Type Fusing Machines

- Flatbed Fusing machine

- Cutting Machines

- Auto Cleaning Machine- Spot Removing Machines

- Thread Sucking Machine

- Needle Detector Machine

- Industrial Laundry Machines

- Calendering Machine - Flatwork Ironer Pressing Machine- Drying pressing Machine

- Dry Cleaning Machine

- All in one Fully Automatic Industrial Laundry Machine

- Electric and Oil Fired Boilers

- Vacuum Ironing Tables - Industrial Pressing Table

- Laundry Pressing Machine - Hot Plates

- Turn Key Laundry Projects

- Shirt & Trousers Pressing Machines- Automatic

- Jacket Blazers Suits Coats Forming Finishing Pressing Machine

- Shirt Making Machines

- Shoe Washing Machines

- Industrial Carpet Washing Machines

- Sewing Machines

- Industrial Washing Chemical - Solvents

Our Clients