Audaces Apparel CAD CAM

A reference in technological innovation worldwide, with more than 20 solutions developed for the fashion market.

Audaces is a world reference in technological innovation for fashion, developing solutions for the industry of the sector for more than 25 years. Present in more than 70 countries, it is the market leader in Latin America, with a 70% market share. At the beginning of this year, it started to count on a factory in Italy, dedicated to the assembly of machines for Europe. Today, more than 30,000 fashion professionals use Audaces products daily. Audaces' mission is to innovate from the development of affordable solutions, ensuring the rapid deployment of technology in companies of all sizes.

Our goal is to help your company produce more and better

Regardless of the segment of performance, size or geographic location, with Audaces solutions your company can increase productivity, improve product quality and save resources.

The feature belongs to those who innovate every day, who venture into new businesses. This is what Audaces believes,this is the reason for its existence

Claudio Grando President of Odacess

Awarda

Finalist in Make Award Brazil

Innovation Award, IMB-Germany, with Audacss Tower Jet

Highlight as one of the 10 biggest innovation of Brazil, of the last decade, in the VII Conference of Anpei

Finalist in Make Award Brazil

Innovation Award, IMB-Germany, with Audacss Tower Jet

Highlight as one of the 10 biggest innovation of Brazil, of the last decade, in the VII Conference of Anpei

Audaces 360 is an innovative concept of integrating the creation and production steps for you to achieve the success of your collection. A complete solution for you to generate more results, optimizing creative talent and resources through information and practicality. In fashion, whole company has a great challenge: to be assertive in design and profitable in production. Audaces 360 is the ultimate platform you need for your business to meet and exceed this challenge.

Now the power to transform fashion is in your hands.

You can unleash your imagination that Audaces 360 gives you all the support you need to creatively and economically target your collections. Create incredible clothes and be sure of the technical feasibility of performance, even before development or going into production, thanks to the integration of steps. See in detail the Audaces 360 solutions for fashion design:

A powerful tool for stylists

All the needs of fashion design are covered in Audaces 360, with this powerful solution for designers: Audaces Idea. Count on tools for complete technical drawing. The automatic and integrated technical data sheet and pre-cost enable the perfect communication between areas so that the development and production process happens correctly the first time. Everything to facilitate and automate, saving you time to dedicate yourself to research and design, and still meet the short deadlines of the release schedule.

See the advantages for those who use Audaces Idea:

Application and edition of run and localized prints

Application and edition of run and localized prints

Technical design and datasheet integrated in a single solution

Technical design and datasheet integrated in a single solution

Import of modeling for use in the datasheet

Import of modeling for use in the datasheet

Automated datasheet integrated with the management systems

Automated datasheet integrated with the management systems

Tools easy and intuitive

Tools easy and intuitive

Communication between Style and Modeling made easy, avoiding rework

Communication between Style and Modeling made easy, avoiding rework

Automatic modal pre-cost

Automatic modal pre-cost

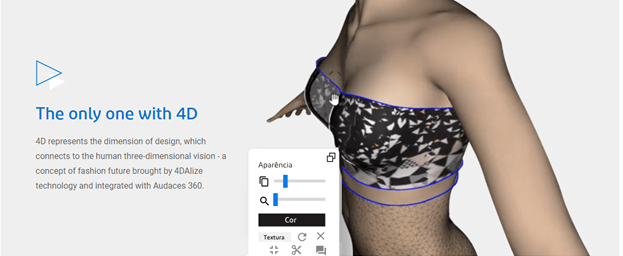

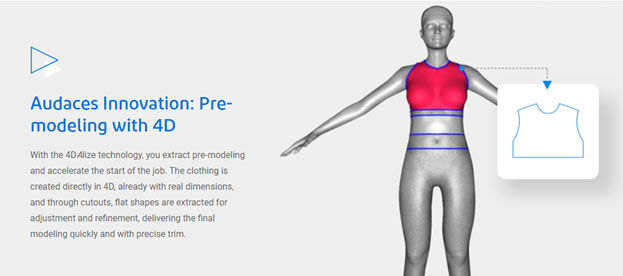

Unleash your imagination and draw incredible clothes in 4D.

Create models directly on a three-dimensional mannequin, using 4DAlize technology. It allows you to create and visualize and simulate the trim of a piece without needing the pattern. A technology developed with the intention of improving and accelerating the process of creating and approving models from a collection. Gain assertiveness and time in creation.

Environment with tree-dimensional human vision to create sketches.

Environment with tree-dimensional human vision to create sketches.

Possibility of digital approval of the collection.

Possibility of digital approval of the collection.

Clear understanding of the modal to be produced.

Clear understanding of the modal to be produced.

optimization of raw material

optimization of raw material

Your development of patterns in the digital era.

Multiply your productivity and reduce costs with Audaces 360 solutions to develop high quality, precision molds, regardless of complexity. It begins here, the guarantee of an exquisite execution of your collection.

Your modeling is definitely in the digital age.

Create patterns from scratch, then manipulate in one click, automatically set gradients, and check out the measurements with all the ease the digital process delivers. Audaces Pattern is an intuitive and easy-to-use solution that streamlines all the modeling work.

See the advantages for those who use Audaces Pattern:

Speed and precision.

Audaces 360 has an intuitive interface that allows you to simply and

quickly, create templates safely, scale and modify existing databases,

right on your computer.

Speed and precision.

Audaces 360 has an intuitive interface that allows you to simply and

quickly, create templates safely, scale and modify existing databases,

right on your computer.

Innovation and Speed

Grade bases and create impressive markers with just a few clicks.

Innovation and Speed

Grade bases and create impressive markers with just a few clicks.

Simple and intelligent

Develop Patterns strait on your computer of simply alter existing

base. Grade your patterns in a simple and dynamic way and reach the

quality you aim for in a fraction of the time.

Simple and intelligent

Develop Patterns strait on your computer of simply alter existing

base. Grade your patterns in a simple and dynamic way and reach the

quality you aim for in a fraction of the time.

Complete system

Create patterns with precision, save time grading bases and crate

quality markers easily.

Complete system

Create patterns with precision, save time grading bases and crate

quality markers easily.

Easy to learn and to use

Our patterns system is the favourite among professional of the

fashion industry and among the biggest and best fashion schools

around the globe.

Easy to learn and to use

Our patterns system is the favourite among professional of the

fashion industry and among the biggest and best fashion schools

around the globe.

Multiple options

Define the sewing process in a simple way when cutting the patterns.

This tool gives the professional a range of options of threads to choose from,

as well as the direction of the warp yarns the cutting will be made.

Multiple options

Define the sewing process in a simple way when cutting the patterns.

This tool gives the professional a range of options of threads to choose from,

as well as the direction of the warp yarns the cutting will be made.

Scan patterns quickly and accurately

Using only one digital photo, you can scan all the paper patterns of your apparel. Pass everything into the computer and even improve your work environment. Accurately and quickly transform bases that can be modified without losing the initial apparel. And most surprising, using only a digital photo it is possible to scan all the paper patterns of your model.

See the advantages for those who use Audaces Digiflash:

Technical design with specific tools for fashion

Technical design with specific tools for fashion

Application and edition of run and localized prints

Application and edition of run and localized prints

After scanning your patterns it still does a lot more for you.

It automatically detects the elements used by the industries and has simple and intuitive tools, as well as an exclusive assistant to scan large patterns. It does not require a special operator and can be operated by anyone.

Simple and intuitive scanning process

Simple and intuitive scanning process

Automatic Detection of Pics and Intuitive Digitalization of Patterns.

Automatic Detection of Pics and Intuitive Digitalization of Patterns.

Exclusive Assistant for Larger Patterns.

Exclusive Assistant for Larger Patterns.

Does not Require Specialized Operator

Does not Require Specialized Operator

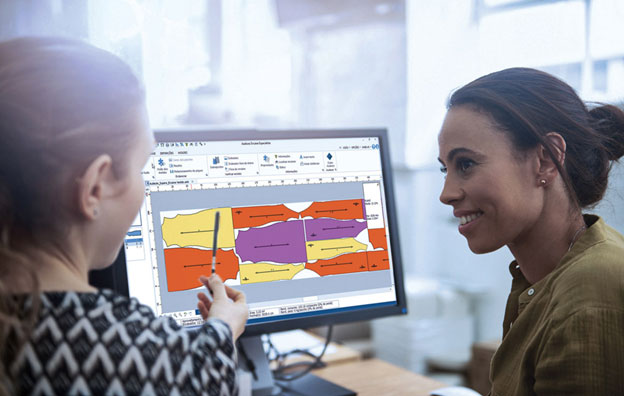

Integration is the concept, efficiency is the goal and productivity is the result.

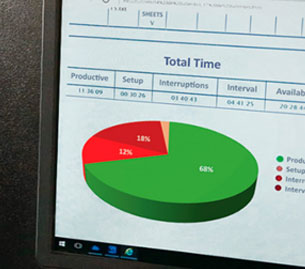

The Audaces 360 integration with Audaces equipment is in line with industry 4.0 concepts. It already provides data that allows analysis of efficiency, decision-making and production planning. The result is increased productivity, also in the production stage of the collection.

Get excellent marker that makes the most of the fabric.

The raw material has a significant weight in the cost of a part, and optimizing this feature is critical to achieve profitability on a large scale. Saving time can mean meeting delivery deadlines and increasing the speed of marketing of collections. Audaces 360 has plug-in options that save time and raw materials by managing and processing marking queues sent by one or more computers. Saving centimeters of fabric turn into meters of profit.

Practicality and Speed

Get automatic markers and enjoy the optimization on fabric consumption.

Practicality and Speed

Get automatic markers and enjoy the optimization on fabric consumption.

Automatic nesting with digital printing

Personalize your production by filling the patterns with stamps for digital printing on fabric. save time and raw material position the stamps over the patterns and print only inside the patterns that are automatically nested with precision and maximum efficiency.

Automatic nesting with digital printing

Personalize your production by filling the patterns with stamps for digital printing on fabric. save time and raw material position the stamps over the patterns and print only inside the patterns that are automatically nested with precision and maximum efficiency.

Fast return on the investment

Centimeters of fabric saving becomes meters of profit.

Fast return on the investment

Centimeters of fabric saving becomes meters of profit.

Efficiency is the goal and productivity is the result

The results allow the analyses for decision taking on planning and optimization of the production.

Efficiency is the goal and productivity is the result

The results allow the analyses for decision taking on planning and optimization of the production.

Let the computer work for you to get the most out of it.

Audaces Supera is a powerful marker server. It saves even more fabric and production time. With it it is much easier to combine perfection and economy in the markers and the return you see already in the first month of use.

Marker Server

Let the computer work for you by creating queues of markers to be calculated, and keep the workstation free.

Marker Server

Let the computer work for you by creating queues of markers to be calculated, and keep the workstation free.

More Usage

Increase the number of algorithms to process the maker, achieving maximum utilization.

More Usage

Increase the number of algorithms to process the maker, achieving maximum utilization.

Workstation released

The marker server does all the service and its workstation and the operator are free to prepare the next ones.

Workstation released

The marker server does all the service and its workstation and the operator are free to prepare the next ones.

Prioritization of the markers

According to production requirements, indicate which fittings should be calculated first.

Prioritization of the markers

According to production requirements, indicate which fittings should be calculated first.

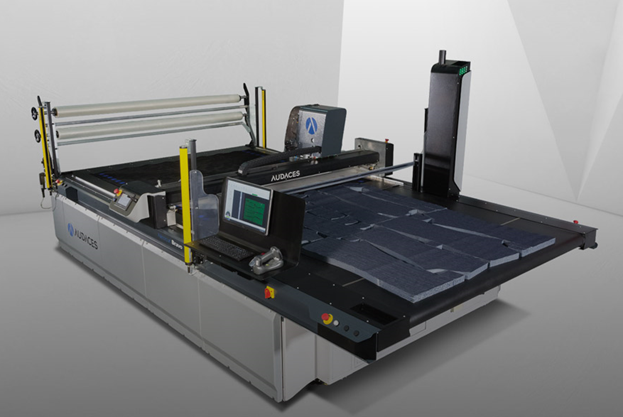

The most intelligent and safe automatic cutting machine in the world.

Audaces Neocut Bravo is a machine for the Industry 4.0. With short deadlines, new product requirements and an increasingly competitive landscape, companies need to adapt and respond to change quickly. Holding information to create efficient planning is critical to getting the best results. With Neocut Bravo, the time, day, week and month of production are timed, aligned with your company goals and automatically provided for you to make decisions in complete safety. The continuous monitoring of the working conditions allows remote maintenance, remote diagnosis and the quick resolution of any situation. Manage better with the intelligence of Neocut Bravo integrated with the Neocut Mobile application to prevent losses and speed up your production. Keep up to date in real time to produce more.

A global project. The only one manufactured in Brazil and Italy.

See the 6 great advantages for those who use Audaces Neocut Bravo:

The innovations developed by Audaces are already anticipating the future of the industry 4.0 in fashion, where all process management can be done with accurate, integrated data provided by intelligent equipment in real time and with remote access. This means that your production may literally be in the palm of your hand. On your smartphone, for example. It's the Internet of Things (IoT) coming into your industry. With short lead times, new product demands and an increasingly competitive market, the fashion industry needs to adapt and respond to those changes quickly. When we speak of automatic cutting, delivery on time, of perfectly cut pieces, we speak of Audaces Neocut Bravo.

Integration is the concept, efficiency is the goal and productivity is the result.

But all the innovation promoted by Audaces, comes not simply from the application of new technologies. It is the result of the practical accompaniment of the day-to-day production of our customers, listening to the suggestions of those who work intensely to improve processes and results. Audaces is present throughout the production cycle, from creation to execution, so it is able to relate information and perfect systems. Each automation project is unique, but it takes advantage of all the experience and knowledge already acquired. The support we give you does not end in the acquisition. You become a partner with Audaces, the technology owner, and you can keep your equipment up-to-date. Count on our experts to make the right decision and to achieve and exceed your goals. Our focus is the sustainability of your business.

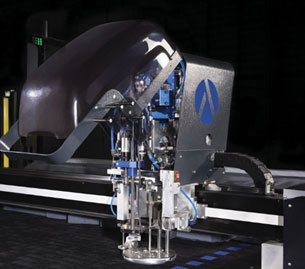

The cutting head of Neocut Bravo is a true electronic brain

More than 300 sensors ensure that neocut bravo adopts the best cutting condition for different type of materials and different layer height. With them, the productivity in the exquisite of the projects is assured, without losses, in scale and with finish.

Zero Spacing and High cut Quality

Cutting with zero spacing between the patterns, the machine sets the starting points automatically, guaranteeing cutting from the first to the last layer with maximum use of raw material.

Robust for cutting Heavy Materials and Delicate for lightweight fabrics

The Intelligent blade system and sensors enable neocut bravo to accurately cut dense or light materials. The bending of the cutting blade is monitored continuously to ensure the perfect cut, regardless of the complexity of the patterns or the characteristics of the fabric. Contours markings and norths are made with precision.

Safety is not a mere detail in Neocut Bravo

Neocut Bravo is the safest cutting machine in the world.it interrupts its operation as soon as the machine’s work area is invaded. The return to the operation is automatic and instant, at the point that it stopped at without the intervention of the operator.

Operating it is simple and Intuitive

Easy to use and easy to learn, Neocut bravo has an interface that makes it easy to learn all of its features.

The best cost-benefit ratio in the market

With commercial electronics and first-line parts ,Neocut bravo guarantees low maintenance costs and energy savings.

Do more and better in less time with the automatic fabric spreading machine.

Audaces Linea automatic spreader accelerates the production and marketing of your products. Schedule multiple same-day cuttings with simple touches on the machine's touch screen. Your company will gain dynamism and autonomy and raise the standard of products.

See the advantages for those who use Audaces Linea

Tension control

Fabric layers are made without the fabrics (or other materials) undergoing stress. The machine is parameterized according to each material, ensuring quality in the finished part.

Tension control

Fabric layers are made without the fabrics (or other materials) undergoing stress. The machine is parameterized according to each material, ensuring quality in the finished part.

Fabric Layers Quality

The brilliance of audaces idea accounts the measurements and quantity of sheets established for each spread. If any fault is detected on the fabric, it is possible to interrupt the process and resume the spread from starting point or from where left off.

Fabric Layers Quality

The brilliance of audaces idea accounts the measurements and quantity of sheets established for each spread. If any fault is detected on the fabric, it is possible to interrupt the process and resume the spread from starting point or from where left off.

Versatile and efficient for spreads

The Audaces Pratica spreader table is versatile and multivalent. It carries various loads of spreads, offers the function of inflation and allows to enlarge the production adjusting to the layout of each company.

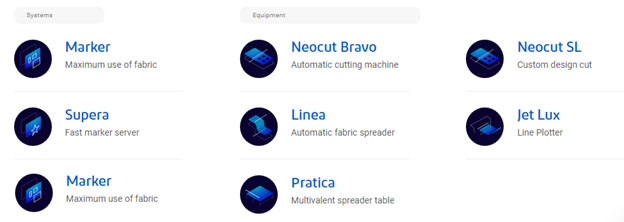

Our Products

- Audaces Apparel Cad CAM

- Garment Cutting Printing Plotters

- Fabric Inspection Machine

- Conveyor Type Fusing Machines

- Flatbed Fusing machine

- Cutting Machines

- Auto Cleaning Machine- Spot Removing Machines

- Thread Sucking Machine

- Needle Detector Machine

- Industrial Laundry Machines

- Calendering Machine - Flatwork Ironer Pressing Machine- Drying pressing Machine

- Dry Cleaning Machine

- All in one Fully Automatic Industrial Laundry Machine

- Electric and Oil Fired Boilers

- Vacuum Ironing Tables - Industrial Pressing Table

- Laundry Pressing Machine - Hot Plates

- Turn Key Laundry Projects

- Shirt & Trousers Pressing Machines- Automatic

- Jacket Blazers Suits Coats Forming Finishing Pressing Machine

- Shirt Making Machines

- Shoe Washing Machines

- Industrial Carpet Washing Machines

- Sewing Machines

- Industrial Washing Chemical - Solvents