Shirt & Trousers Pressing Machine - Automatic

Fully Automatic pressing Solution

Robo Shirt Form Finisher Shirt Press

Cuff and Collar press

Feature:

- Both the machine is programmed by three times: steam, Hot air Cold air. The combination of three cycles makes the garment press perfectly.

- The machines are constructed from stainless steel (INDX AISI 304); special powder coating on the body enables long rust free life.

- The AG-94 IB with inbuilt boiler is an energy saving garment former. The steam condensate can return to the steam generator for lower steam consumption and does not require a steam trap.

- Available extras: Steam iron assembly, steam Gun, water spray gun, alternative dummies which are Interchangeable with the standard utility dummy which is supplied with the basic unit.

Robo Form Finisher for Shirts

Robo Form Finisher for Shirts

Technical Specification

| Model | AG-94 Premium | AG-94 Ultra Premium |

|---|---|---|

| All working pressure | 6.8 bar | 6-8 bar |

| Steam working pressure | 4-5 bar | 4-5 bar |

| Overall size (In mm) | 15-20 kg/hr | 15-20 kg/hr |

| Air inlet ¼” | 975*430*1400 | 1500*690*1600 |

| Steam inlet | ¼” | ¼” |

| Boiler drain | ½” | ½” |

| Pump motor | 2 kw | 2 kw |

| Return Outlet | ½” | ½” |

| Fan motor | 1.5 kw | 1.5 kw |

| Voltage | 415 V 3ph | 415 V 3 ph |

Topjet: Ultra Premium

Topjet: Premium

Feature:

- Programmable cycle adjustable by timer control

- Optional LCD multilingual touch screen microprocessor control

- Stainless steel waistband forms

- Two automatic pivoting clamps for legs (external clamping)

- Readout for waistband

- Super battery for even heating temperature

- Fan with air flow regulation (2hp)

- Adjustable Height

- Pneumatic device to control the legs tensioning

- Also available in double steam battery for leather/denim garment.

- Stainless steel waistband forms (interchangeable, min. width 200mm. diam)

- Two automatic pivoting clamps for legs (external clamping)

- Readout for waistband

- Electric super heater for steam up to 300 degree C

- Fan with air flow regulation (2Hp)

- Automatic cycle adjustable by timer control (6 language 100 programs)

- Manual height adjustable

Technical Specification:

| Model | AG-92 Premium | AG-92 Ultra Premium |

|---|---|---|

| Required Power | 415 V 3ph | 415 V 3ph |

| Fan Shoot | 1.5 kw | 1.5 kw |

| Steam Inlet | ½” | ½” |

| Return | ½” | ½” |

| Steam Working pressure | 4-6 bar | 4-6 bar |

| Steam Consumption | 15-20 bar | 20-25 bar |

| Compressed air supplied | ¼” | ¼” |

| Air Compressor Pressure | 10 bar | 10 bar |

| Air Compressor Consumption | 2 NI/ciclo | 2 NI/ciclo |

| Overall size (in mm) | 1300*750*2070 | 1300*1050*2070 |

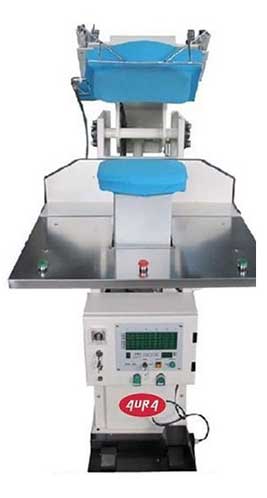

AG-FASP-1011

AG-FASP-1012

Shirt Pressing Machine

| Features |

|---|

| Aluminum buck is suitable for garment (Customizable) |

| Automatic LED |

| Controller (8 programs) Set:- Close, Press, Steam, Vacuum) |

| Period of step:- 0.5/1.0/1.5/2.0/2.5 second |

| Stainless steel board, steam heating system |

| Output single on electric board (easy to check faulty) |

| Stainless Steel Board, Steam heating system |

| Top Buck Steam spray ( steam chamber supply much volume |

| Bottom buck has vacuum |

| Famous Pneumatic parts |

| Dimension L*W*H:- 900x1200x2350mm |

AG-FASP-1015

AG-FASP-1013

AG-FASP-1014

| Features |

|---|

| Aluminum buck is suitable for garment (Customizable) |

| Automatic LED |

| Controller (8 programs) Set:- Close, Press, Steam, Vacuum) |

| Period of step:- 0.5/1.0/1.5/2.0/2.5 second |

| Stainless steel board, steam heating system |

| Output single on electric board (easy to check faulty) |

| Stainless Steel Board, Steam heating system |

| Top Buck Steam spray ( steam chamber supply much volume |

| Bottom buck has vacuum |

| Famous Pneumatic parts |

| Dimension L*W*H:- 900x1200x2250mm |

Shirt Pressing Solution

Model: PMM-SS-2C1

Cuff Turn and Press Machine

Model: PMM-PCS-PLC

Automatic Pocket Cereaser

Model: PMM-SVF-1

Automatic Sleeve vent fold and press machine

Model: PMM-BFP-1

Shirt front creasing machine

Features

| Pressing the edge of the cuff helps the sewing process. |

| Able to fix and press the cuff. |

| Automatic temperature control |

Features

| Special for folding of shirts sleeve vent. |

| Able to fold a pair. |

| Control by micro computer. |

| Built in an automatic staking device. |

| Laser light is used for aliening the fabric. |

| Different mould can fold different types of sleeves vent. |

| Able to fold 3000-3600 pairs per shifts. |

Features

| PLC programmable logic control, fast and durable. |

| Suitable to fold any pocket shape (square, round, triangle, heart, and hexagon etc.) |

| Automatic staking device and air vacuum system to keep the pocket in excellent shape. |

| Temperature and time can be adjusted according to the material. |

| Both foot and button control is available. |

Features

| Machine is design to fold shirt front. |

| Laser light is used for aligning the fabric. |

| Average of 1900 fold per shifts. |

| Able to automatically stack up the material after finish. |

| Option the install lining cutter for worker to put the lining tape inside the shirt front. |

Shirt Pressing & Folding Table

Features

- Pneumatically operated system that works like a robot and assists to press & fold Jackets perfectly

- Gives much high productivity and quality

- Adjustable neck mould for different neck sizes and shapes

- Consists of aluminum gravity die casting disc supporting 5 CNC machined moulds with synchronized indexing and locking mechanism

- Automatic movement of stainless steel back plate, aided by pneumatic cylinder, ensures that the center of the neck/collar perfectly aligned with the buttons.

- Button guard helps to place button in center line for giving a balanced fold

- Collar and lapel forming function to enhance their finish and shape

- Equipped with high quality and accurate thermostat

- Aluminum casted heaters.

- Ergonomically designed with elegant look

- Two models available: automatic and manual

AG-203/SF Premium

Legger & Topper

Model AG-FA-261

Features

| Scissors - type close & press. |

| Metal buck is suitable for garment (customizable) |

| Automatic led controller (8 programs) |

| (Set close, press, steam, vacuum) |

| Period of Step : 0.5/1.0/1.5/2.0/2.5 second |

| 3 level safety protection device. |

| Output signal on electric board (easy to check faulty) |

| 180 mm length shock absorber (long life) |

| Stainless steel board, Steam heating system. |

| Top buck steam spray (Italy-made value). |

| Bottom buck has vacuum. |

| Famous buck has vacuum. |

| Famous pneumatic parts. |

| Dimension L*W*H : 900*1200*1300mm. |

Model: AG-FA-262

Features

| (Set, close, press, steam, vacuum) |

| Period of Step : 0.5/1.0/1.5/2.0/2.5 second |

| 3 level safety protection device. |

| Output signal on electric board |

| (easy to check faulty) |

| 180 mm length shock absorber (Long Life) |

| Stainless Steel board |

| Steam heating system |

| Top buck steamspray (Italy-made value). |

| Bottom buck has vacuum. |

| Famous pneumatic parts. |

| Dimension L*W*H : 900*1200*1300mm. |

Features

| Pneumatic Pressure adjustment for every type of fabric. |

| Sensitive ironing with Pat – pat Ironing function. |

| Safety frame for operate safe optional. |

| Computer (PLG) control. Laser pointer. |

Mennual Legger & Topper

Model: AG-M-261

Model: AG-M-262

| Model | AG-M-261 | AG-M-262 | AG-M-263 |

|---|---|---|---|

| Mode of Operation | Manual | ||

| Heating mode of upper and lower moulds | Steam | ||

| Mode of Steam-jetting | Hand-operation for upper mould | ||

| Mode of heating | Manual | ||

| Steam Working Pressure | 0.4-0.6 Mpa | ||

| Steam Consumption | 15-20 kg/h | 15 kg/h | 10 kg/h |

| Net Weight | 260 kg | 210 kg | 220 kg |

| Dimensions:(L*W*H) | 1320*1260*1280 mm | 1270*1260*1280 mm | 1270*1280*1660 mm |

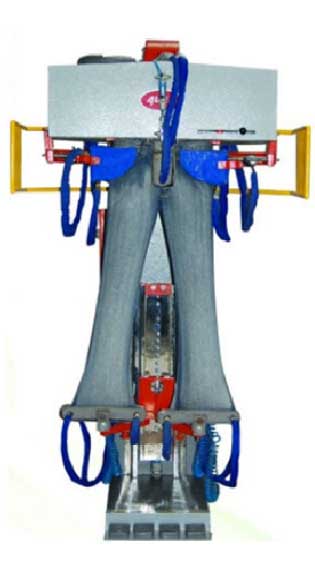

TOPJETS MACHINE trouser finishing Machine

AG-92 Topjet (Ultra Premium)

AG-92 Topjet (Ultra Premium)

Features

- Programmable cycle adjustable by timer control

- Optional LCD multilingual touch screen microprocessor control

- Stainless steel waistband forms

- Two automatic pivoting clamps for legs (external clamping)

- Readout for waistband

- Super battery for even heating temperature

- Fan with air flow regulation (2hp)

- Adjustable Height

- Pneumatic device to control the legs tensioning

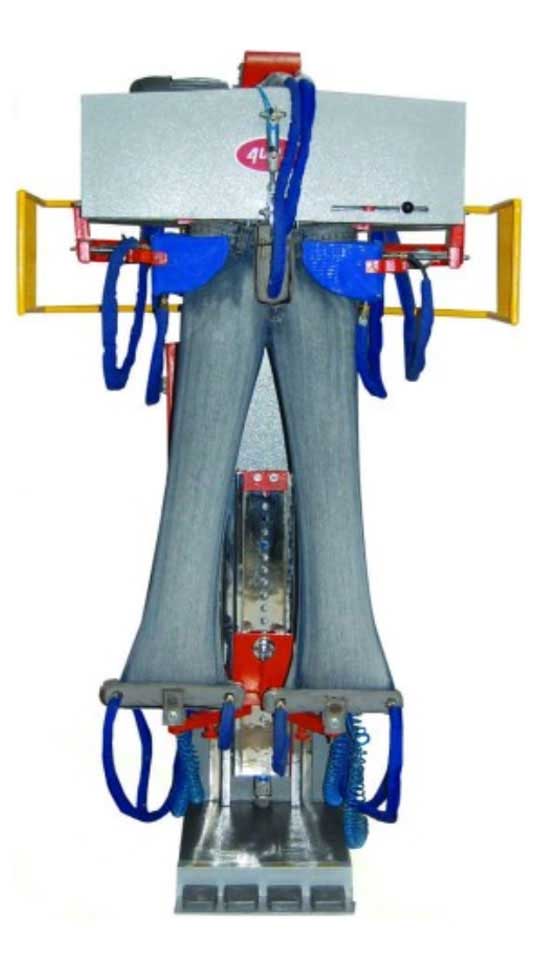

AG-92 Topjet (Premium)

Features

- Stainless steel waistband forms (interchangeable, min. width 200mm. diam)

- Two automatic pivoting clamps for legs (external clamping)

- Readout for waistband

- Electric super heater for steam up to 300 degree C

- Fan with air flow regulation (2Hp)

- Automatic cycle adjustable by timer control (6 language 100 programs)

- Manual height adjustable

- Pneumatic/mechanical device to control the legs tensioning

- Supplied with anti stretching devices to main the sizes originally set by the production.

CONTACT US FOR TECHNICAL SPECIFICATION

Trouser Pressing Machine

AG-FATP-1101

AG-FATP-1102

AG-FATP-1104

AG-FATP-1103

AG-FATP-1105

Features

| Pneumatic Pressure adjustment for every type of fabric. |

| Sensitive ironing with Pat-pat ironing functions. |

| Safety frame for operator safe optional. |

| Computer (PLG) control. |

| Laser Pointer. |

Features

| Aluminum buck is suitable for garment (Customizable) |

| Automatic LED |

| Controller (8 programs) Set:- Close, Press, Steam, Vacuum) |

| Period of step:- 0.5/1.0/1.5/2.0/2.5 second |

| Stainless steel board, steam heating system |

| Output single on electric board (easy to check faulty) |

| Stainless Steel Board, Steam heating system |

| Top Buck Steam spray ( steam chamber supply much volume |

| Bottom buck has vacuum |

| Famous Pneumatic parts |

| Dimension L*W*H:- 900x1200x2250mm |

Features

| Aluminum buck is suitable for garment (Customizable) |

| Automatic LED |

| Controller (8 programs) Set:- Close, Press, Steam, Vacuum) |

| Period of step:- 0.5/1.0/1.5/2.0/2.5 second |

| Stainless steel board, steam heating system |

| Output single on electric board (easy to check faulty) |

| Stainless Steel Board, Steam heating system |

| Top Buck Steam spray ( steam chamber supply much volume |

| Bottom buck has vacuum |

| Famous Pneumatic parts |

| Dimension L*W*H:- 900x1200x2250mm |

Features

| Aluminum buck is suitable for garment (Customizable) |

| Automatic LED |

| Controller (8 programs) Set:- Close, Press, Steam, Vacuum) |

| Period of step:- 0.5/1.0/1.5/2.0/2.5 second |

| Stainless steel board, steam heating system |

| Output single on electric board (easy to check faulty) |

| Stainless Steel Board, Steam heating system |

| Top Buck Steam spray ( steam chamber supply much volume |

| Bottom buck has vacuum |

| Famous Pneumatic parts |

| Dimension L*W*H:- 900x1200x2350mm |

Features

| Stainless steel waistband forms (interchangeable, min. width 200mm. diam) |

| Two automatic pivoting clamps for legs (external clamping) |

| Readout for waistband |

| Electric super heater for steam up to 300 degree C |

| Fan with air flow regulation (2Hp) |

| Automatic cycle adjustable by timer control (6 language 100 programs) |

| Manual height adjustable |

| Pneumatic/mechanical device to control the legs tensioning |

| Supplied with anti stretching devices to main the sizes originally set by the production. |

| Famous Pneumatic parts |

| Dimension L*W*H:- 900x1200x2350mm |

Features

| Pneumatic Pressure adjustment for every type of fabric. |

| Sensitive ironing with Pat-pat ironing functions. |

| Safety frame for operator safe optional. |

| Computer (PLG) control. |

| Laser Pointer. |

Features

| Programmable cycle adjustable by timer control |

| Optional LCD multilingual touch screen microprocessor control |

| Stainless steel waistband forms |

| Two automatic pivoting clamps for legs (external clamping) |

| Readout for waistband |

| Super battery for even heating temperature |

| Fan with air flow regulation (2hp) |

| Adjustable Height |

| Pneumatic device to control the legs tensioning |

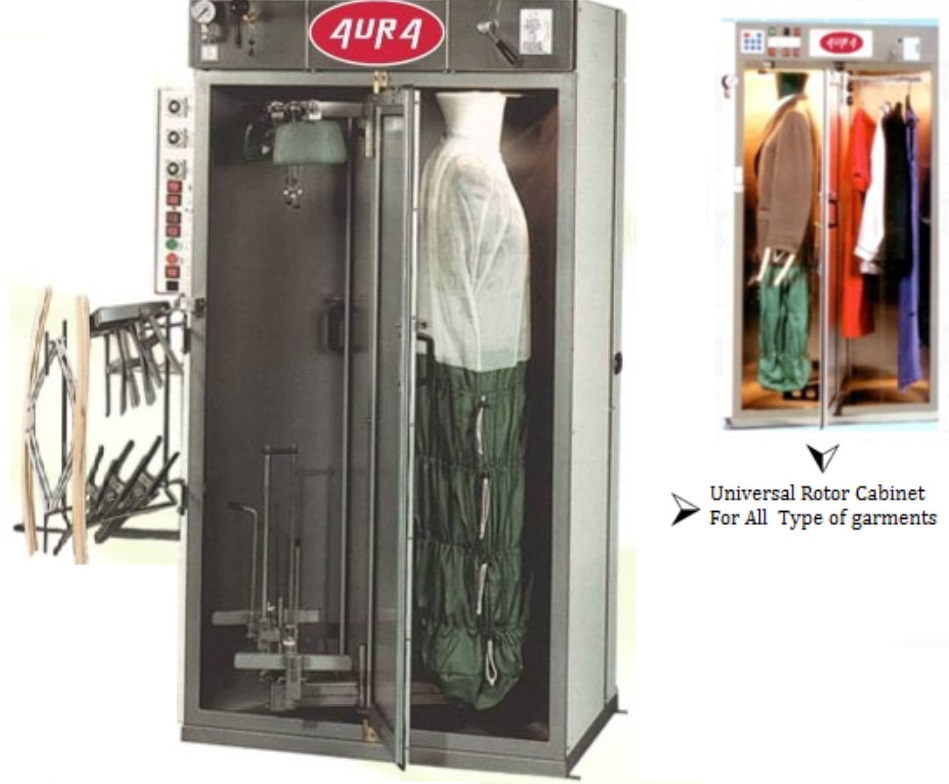

Universal Rotor Cabinet for all type of Garments

The ultimate solution in form finishing, the Pony cosmos revolving finishing cabinet is a flexible system that can be used as a double form finisher, pants topped/Jacket finisher or mini tunnel. The Cosmos system provides a high-production, deskilled operation for retail stores & distribution centers, hotels, uniform rental services, apparel manufactures and dry cleaners.

| Model | Model AURA |

| Required power | 400V./3+N/50 Hz. |

| Water feeding | Hosepipe 13mm |

| Steam Inlet | ½ |

| Return Outlet | ½ |

| Steam working pressure | 4/5 bar |

| Steam Consumption | 16/20 kg/h |

| Boiler drain | ½ |

| Boiler heating | 10/12/15/18 kw |

| Pump motor | 0.6 kw |

| Fan Motor | 0.75 kw |

| Warm air outlet | 160 mm |

| Encumbrance | 1060*1040*1820mm |

| Net weight with boiler | 270 kg |

| Gross weight | 310kg |

| Overall dimensions | 1230*1000*2100mm |

Garment Packing Machine

Universal Garments Finising and Packing Machines

Innovation in Garment Pressing and Packing

Universal Packing machine For all type of Garments

Garment Packing machine

| Best Class Garment Packing Machine | ||

| The Machine comes with less maintained and Compact Design | ||

| With Longer Functional Life | ||

| Ideal for every type of Garment Packing | ||

| Specialized for every type of Indian and western wear | ||

| An efficient and convenient way for laundry Outlet |

Our Products

- Audaces Apparel Cad CAM

- Garment Cutting Printing Plotters

- Fabric Inspection Machine

- Conveyor Type Fusing Machines

- Flatbed Fusing machine

- Cutting Machines

- Auto Cleaning Machine- Spot Removing Machines

- Thread Sucking Machine

- Needle Detector Machine

- Industrial Laundry Machines

- Calendering Machine - Flatwork Ironer Pressing Machine- Drying pressing Machine

- Dry Cleaning Machine

- All in one Fully Automatic Industrial Laundry Machine

- Electric and Oil Fired Boilers

- Vacuum Ironing Tables - Industrial Pressing Table

- Laundry Pressing Machine - Hot Plates

- Turn Key Laundry Projects

- Shirt & Trousers Pressing Machines- Automatic

- Jacket Blazers Suits Coats Forming Finishing Pressing Machine

- Shirt Making Machines

- Shoe Washing Machines

- Industrial Carpet Washing Machines

- Sewing Machines

- Industrial Washing Chemical - Solvents

Our Clients